High accuracy electric muffle furnace SNOL 13/1100 LED is designed for combustion loss determination (loss on ignition) with the assistance of added balances, which weigh the materials before, during, and after the process. This could also inform about the completion of the process – as soon as the weight ceases to decrease. To eliminate gases or smoke that are released during thermal processing, an exhaust system may be installed additionally. It is used with a variety of materials like, for example, sediment, sludge, soil, waste, or inorganic materials such as cement, lime, calcinated bauxite, and refractories, firing up to 1100°C. The furnace is an excellent fit for scientific laboratories, educational institutions, ceramic studios and is used in medicine and industry.

BASIC MODEL

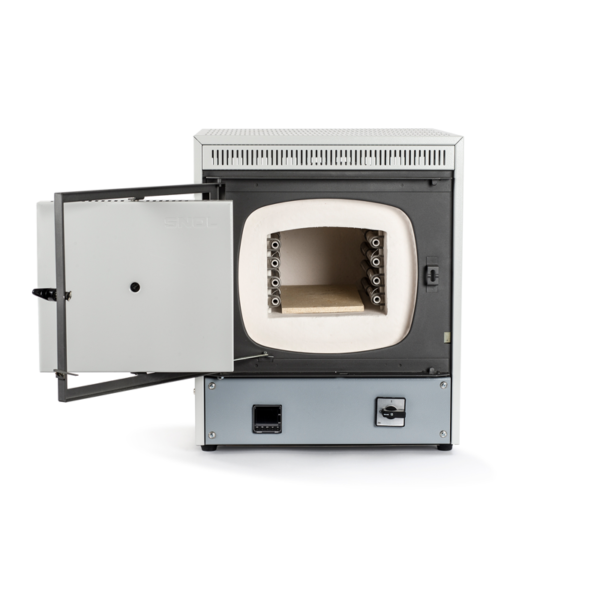

- One piece, high thermal efficiency, vacuum-formed ceramic fiber chamber;

- Heating elements, embedded in a vacuum formed fiber, are inside four walls of the chamber;

- Outside casing – metal sheet, powder painting – grey;

- Door opens upwards;

- Door safety interlock switch;

- Control panel is placed in the underpart of the furnace;

- Microprocessor – temperature controller;

- Ceramic bottom plate mounted to a ceramic tube;

- Fast heating time due to low thermal mass construction;

- Low power consumption;

- Good stability and uniformity.

OPTIONS

- Balances;

- Process observation window (o 35 mm) up to 1100 °C;

- Fan-assisted chimney for air extraction;

- Additional ceramic hearth plates;

- Buzzer;

- Digital timer;

- Protection against overheating;

- Data recorder;

- RS232/RS-485/USB interface;

- Calibration of temperature measurement system;

- Table for supporting the furnace;

- Protective gas atmosphere;

- Gas box up to 1100 °C;

- Metal tray;

- Additional 1 year warranty.